NED AMINO-M

DL-Methionine (99% Feed Grade)

NED AMINO-M is a high-purity DL-Methionine (Feed Grade, 99%), a vital amino acid essential for maintaining balanced nutrition in modern feed formulations.

Methionine supports protein formation, metabolic activity, and overall nutrient utilization — making it a key component in diets based on cereals and plant proteins.

Incorporating NED AMINO-M helps achieve optimal amino acid balance, improves feed formulation flexibility, and ensures consistent nutritional support across multiple livestock categories.

Applications

Ideal for poultry, swine, aquaculture, and ruminant feeds — supports balanced nutrition, efficient growth, and overall performance.

Key Features & Benefits

Supports Nutrient Utilization

Contributes to efficient protein synthesis and helps maintain appropriate amino acid ratios in the diet.

Helps Maintain Muscle Development

Provides essential sulfur-containing amino acids that assist in normal tissue formation and maintenance.

Balances Amino Acid Profile

Complements Lysine, Threonine, and other essential amino acids to support complete nutritional formulation.

Supports Metabolism & Enzyme Functions

Acts as a precursor for various metabolic compounds involved in normal physiological processes.

Improves Feed Formulation Flexibility

Allows nutritionists to adjust protein levels more precisely, offering cost-effective diet optimization.

Enhances Overall Feed Quality

Helps reduce nutrient imbalances, supporting consistent and uniform feed production.

| Parameter | Specification |

|---|---|

| Product Name | DL-Methionine (Feed Grade) |

| Brand Name | NED AMINO-M |

| Chemical Formula | C₅H₁₁NO₂S |

| Purity | ≥ 99.0% (on dry basis) |

| Appearance | White to light yellow crystalline powderr |

| Odor | Characteristic amino acid odor |

| Moisture Content | ≤ 0.3% |

| Bulk Density | 0.45–0.65 g/cm³ |

| Solubility | Sparingly soluble in water |

| pH (10% Solution) | 5.5 – 7.0 |

| Shelf Life | 24 months from date of manufacture (sealed) |

- Storage & Handling

Store in a cool, dry, and well-ventilated environment.

Protect from moisture, heat, and direct sunlight.

Keep packaging sealed after use to maintain product stability.

Avoid exposure to strong oxidizing and alkaline materials.

Recommended storage temperature: below 30°C.

Shelf life: 60 months under proper storage conditions.

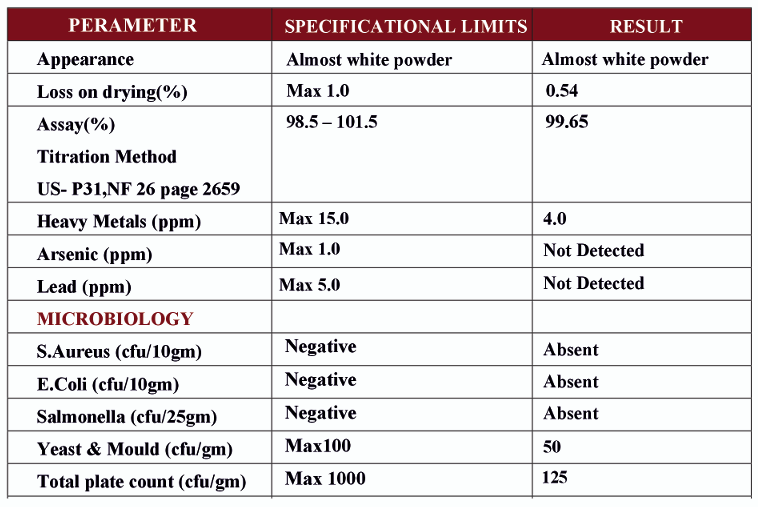

- Quality Assurance

Purity and assay parameters checked for every batch.

Consistent monitoring of particle size and flow characteristics.

Routine evaluation of moisture levels and physical integrity.

Traceability maintained from raw material stage to finished product packaging.